Kenosha Reuse Discussion Board > WAUKEEGAN, IL

> Commercial

> Mechanical

> Refurbished

> No Warranty

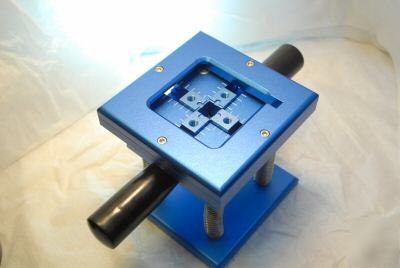

> Bga reballing rework station stencil 0.3MM 0.6MM 0.76MM

Bga reballing rework station stencil 0.3MM 0.6MM 0.76MM

Up for sale is 1 set BGA reballing fixture with 0.3mm, 0.6mm, 0.76mm Stencil

If you are repairing the BGA and you find extremely hard to hand place each solder ball back to the BGA solder pad. This is the one you need for improve the quality and accuracy of reballing!

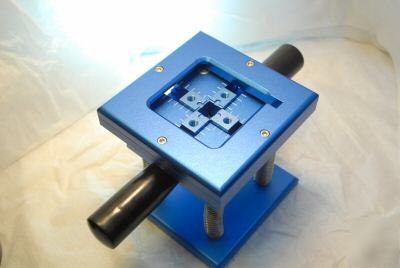

Before reballing, you need to clean the chip of excess solder the bottom by copper tape, flux and alcohol

1. To spread a thin layer of Flux on the BGA by cotton bud

3. fix the stencil (stencil hole to BGA pad)

4. Use Kapton tape to mask the un-use stencil hole, if the stencil is custom made, this step can be skipped

5. Apply the solder ball and spread them into the holes.

7. Use the hot air blower to blow the stencil gently and let the ball melt, the solder ball will solder on the chip solder pad

8. Push the handle down and take away the upper lid and take the reballed chip out.

Different size of stencils, solider ball (Leaded and ROHS) are available, please check out listing.