Kenosha Reuse Discussion Board > RACINE, WI

> Commercial

> Electrical

> New

> No Warranty

> 27 spindle 32MM weeke BP15 boring head for cnc router

27 spindle 32MM weeke BP15 boring head for cnc router

27 SPINDLE BORING BLOCK FOR CNC ROUTER

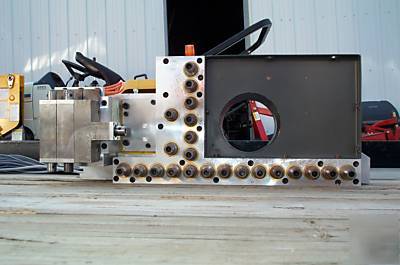

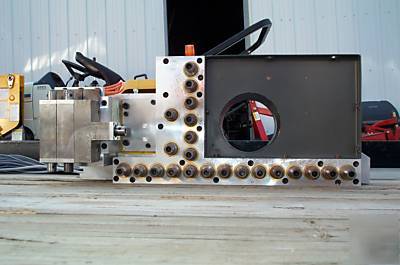

THIS IS A HIGH QUALITY GERMAN BUILT WEEKE DRILLING HEAD IN EXCELLENT CONDITION.

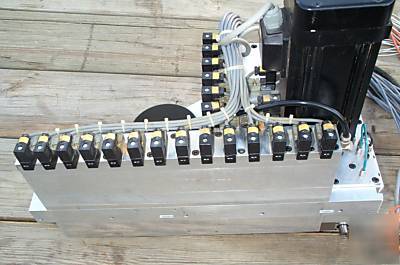

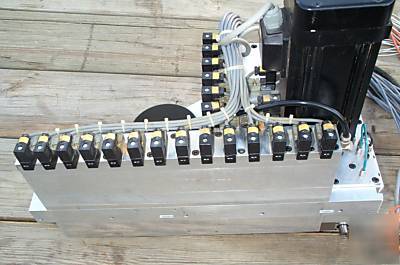

14 Vertical Spindles on 32mm Centers on the Y Axis

7 Vertical Spindles on 32mm Centers on the X Axis (With One Shared with the Y Axis)

2 Vertical Spindles Offset 16mm and 32mm from the X Axis Spindles and Spaced 64mm Apart For Larger Bits Like a 35mm Hinge Drill, etc.

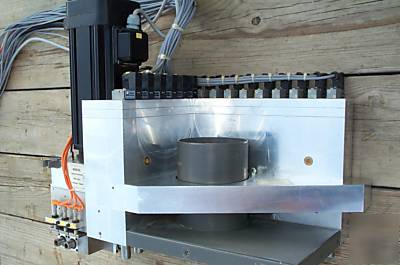

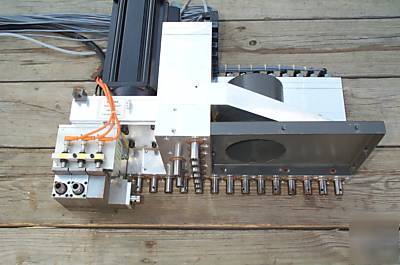

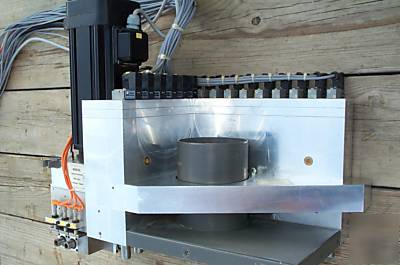

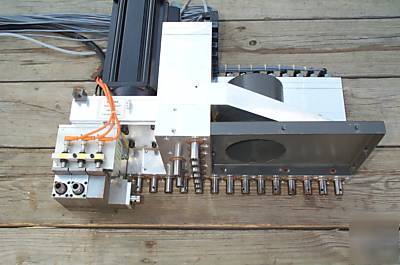

2 Horizontal Spindles to the Left

2 Horizontal Spindles to the Right

1 Horizontal Spindle Pointing Forward from the Back

The spindles All have a 10mm Plain Bore and a Set Screw to hold the Bits.

This Boring Head was set up to use 70mm long bits

Also Included is the Rectangular Dust Hood with Anti-Static Brushes on all 4 Sides (not pictured but in great condition).

Spindles are Gear Driven together by the Main 3450RPM 3 Phase Motor and each spindle alternates from a LH to a RH rotation.

All Vertical Spindles have Built-In Solenoids and work off of a Single Air Supply. When Actuated they Individually Pneumatically Stroke Down into Position and are Fed into the Workpiece by your Z-Axis Drive Motor. You can actuate One or All or any Combination of Spindles into Position via your Programmable Output and when solenoids are released the Spindles are Spring Returned.

The Horizontal Spindles require Three - 3 Way External Solenoid Valves (not included) to Activate and Retract them. One Left and One Right Horizontal Spindle are on one Cylinder, the next Left and Right Spindles are together and the Foreward Facing Spindle is on yet another cylinder. There are Proximity Sensors mounted to each of the three Horizontal Drill Cylinders to Sense whether they are in the Up or Down positions.

Ther are Grease Zerks Strategically placed and Labeled for Years of Trouble Free Drilling.

The motor, sensor and solenoid leads are roughly 7 feet long