Kenosha Reuse Discussion Board > GURNEE, IL

> Commercial

> Economical pellet mill, wood, biomass, or animal feed

Economical pellet mill, wood, biomass, or animal feed

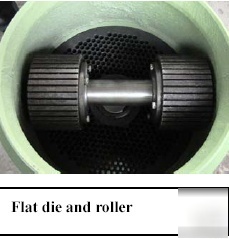

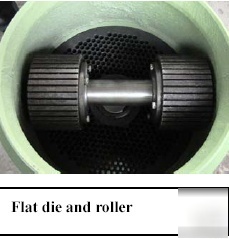

ATFP200 Flat Plate Pellet Mill. This Mill is designed to take ground wood <5mm with a moisture content of ~15% and press up to 265 lbs/Hr. of pellets.

A Note of Caution: There is another pellet company based in Illinois that claims this model will produce 650lbs per hour. It will not. Don't be fooled.

With the rapid price rise of petroleum products in recent years has come a corresponding interest in and rapid development of the wood pellet industry. There are two different methods of producing the wood pellets. The ring and die system and the flat plate process system. The Flat Plate wood pellet press has become very popular around the world because It has the advantage of a low price, low energy consumption and a high capacity output. We manufacture both types of pellet mills and all the auxillary components to create a complete pellet manufacturing plant. This is the least expensive of our pellet mills, it is a great choice for the small farm, saw mill and/or family that wishes to make their own pellets. Making your own pellets is much like cutting your own firewood. It is time consuming hard work, but the end result is a vastly reduced cost of heating your home or business. This mill, like its larger brethren is capable of making fuel pellets from renewable energy materials such as wood, sawdust, biomass and many other agro-waste byproducts. Making your own pellets takes material that would otherwise be plowed under, or sent to a public landfill and converts it into pellets that currently sell for upwards of two hundred dollars per ton. Making your own pellets for consumption in your own home is very satisfying and can help cut your home heating bills dramatically, if you have a wood pellet burning stove.

**Be Aware that additional binding agents may need to be added to the pelletizing process depending on the material being used. During testing, binder agents like paraffin wax, heavy molasses, and different tars added to the material being processed added brilliance to the appearance of the final pellets and helped them bind together better and burn hotter.

Electric Model 7.5KW 3 Phase 220V 60hz .. Mod# ATFP200B..... $1670.. 550 lbs

Electric Model Without Electric Motor .. Mod# ATFP200B-BARE. $1126.. 355 lbs

Diesel Model With 15hp Diesel Engine .. Model ATFP200A ..... $1754.. 600lbs

Electric Start Option for Diesel Powered Model 12V .............. $322

Diesel Model Without the Engine ....... Model ATFP200A-Bare... $1111 .. 355 lbs

Spare Die for Model ATFP200 ...................................................... $95

Spare Rollers for Model ATFP200 ............................................... $106

Feel free to contact me with any questions. (***)-952-1903, or email me ****@customcpu.com