Kenosha Reuse Discussion Board > CALEDONIA, WI

> Commercial

> Electrical

> Refurbished

> New fadal parts - oem baldor high torque spindle motors

New fadal parts - oem baldor high torque spindle motors

VMC Electric, LLC - All Spindle Motors: Standard, High and Very High Torque

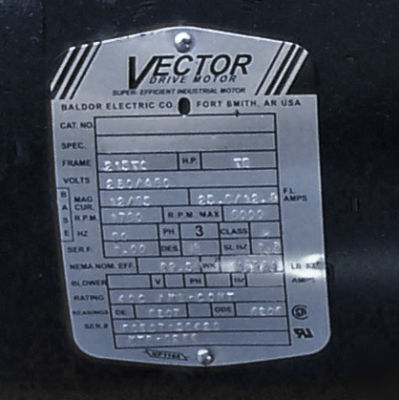

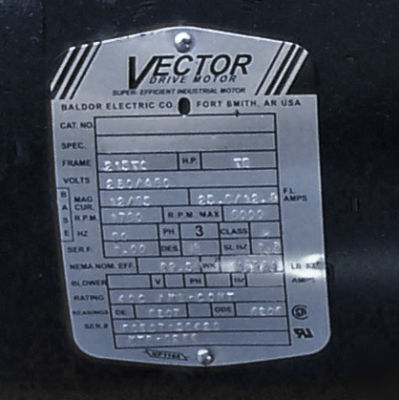

Baldor Motors for Fadal Machines

- High Torque 15 HP Spindle Motor

- Close Loop Vector or Inverter

Typical Online Repair Exchange (10+ years old) -

$975 repair (6 month warranty) +

2 weeks downtime or more if it doesn't work (see below)

- No Core Deposit and No Core Return Freight Required!

Original Equipment: This is a brand new Baldor Spindle Motor, not a "repair" or "replacement" model.

Replaces all 15 HP Fadal Spindle Motors: Directly interchangeable with all Fadal HT machines, except models using not using the Fadal CNC Control.

Upgraded Encoder: Every motor comes with a new, high quality encoder from Encoder Products Inc. Instead of using the old, plastic US Digital encoder, our new motors come with this high end $375 encoder.

Vector Technology: New ENERGY EFFICIENT MOTORS (EEM) saves money even after the purchase! (see below for details)

For any questions about this motor or if you need help identify a bad motor:

Call Us Toll Free 1-(***)-765-9838 or Click "Ask The Seller".

True Fadal Knowledge and Experience you can Trust:

VMC Electric was started by one of the original family members of Fadal Engineering.

Having worked directly in the development of the Fadal CNC control to create many features such as the Rigid Tap and Tool Load Compensation in addition to years of extensive Spindle Drive development and Dyno Testing Experience, we are the true experts as to the exact Fadal spindle drive system requirements for all interrelated components such as Vector Drives, Motors and Spindle Controller software.

Contact us for many more examples of our in depth Fadal knowledge and experience.

Also, having tested and worked directly with Mitsubishi, Sewo and Yaskawa, we are confident our New Baldor Spindle Motor will be your best choice.

Baldor motors for Fadal Machines Glentek motors for Fadal Machines

A common question; it really depends on the reason for failure.

We've seen many attempts to rewind a motor and while they aren't all bad, what they are is not exactly the same electrically as what the Spindle Drive is expecting. Slight variances in the motor winding resistance will cause the Spindle Drive problems running the motors; such as rough running, high current, if it runs at all.

Simply replacing a bearing is only one aspect of the repair process. Over time the windings also fail due to normal usage (current and heat) caused insulation break down and coolant (shop air) contamination. Unfortunately all motor repair shops are not equipped to properly rewind a Vector motor. These aren't just your garden variety AC induction motors.

The motor windings are also very critical to the Spindle Drive. Changing the flux current characteristics in the motor will affect the Spindle Drive performance and in some cases, damage could result to the drive, if it can run the motor at all.

While it might at first seems cost effective to send out a motor to a local motor repair shop when the actual savings might not be that significant, when it's all "said and done".

1) Unfortunately many motor repair shops are not setup to properly rewind these motors to exact specifications. Since they are customized by Baldor for Fadal machines, many different winding designs used by repair shops will effect the Vector performance characteristics programmed into your original Spindle Drive. These motors are not simple AC induction motors that repair shops are accustomed to rebuilding.

3) It's best to replace an open frame motor with our new sealed motors rather than repair the old motor and risk a possible failure again. We've found most motor failures occur from coolant contamination as the machine shop air is circulated through the motor while cooling (open frame motors). Fadal has recently made sealed spindle motors a standard for all machines.

5) Just replacing bearing doesn't address the issue of winding contamination that occurs over time from exposure to "shop air".

Dollar for Dollar, is there a real savings by repairing your motor?

Not really, even if you ignore the issues of a "repaired" motor, consider that the new BALDOR Vector motors are EEM compliant!

They're designed to use less energy and that saves energy costs, up to $459 per year!

Long term savings is always a better investment. - New ENERGY EFFICIENT MOTORS (EEM) Save Money Even After The Purchase!

Here's The Facts How A High Efficiency Motor Saves You Money:

By far the most energy used by the machine is for running the Spindle Motor.

The standard VMC can use up to 11,000 watts, up to 17,000 watts for a High Torque machine.

Yearly Energy Usage Calculation For Standard and High Torque Motors:

- 2000 hours per year (8 hrs/day * 5 days * 50 weeks)

- Average cost of 10 for 1000 watts of electricity, per hour

- Energy Cost Per Year: $1980 - $3060

Yearly Savings potential with a 13.5% more efficient motor: $297 - $459

Energy Savings - $2,970 - $4,590 (over the 10 year average motor life cycle)

An energy-efficient motor saves money in the user's electricity costs, providing long-term savings that pay back the initial investment many times over.

How Can Some Motors Be More Efficient Than Others?

Energy efficiency is basically a matter of managing the magnetic properties in the design and manufacturing process.

Here's five basic design aspects that affect the magnetic performance:

Thinner Lamination Steel - reduces eddy current loses; which misdirect rotational forces.

Materials That Are More Permeable - magnetism with less current.

Greater Cross Section Of Copper Winding - reduced resistance, better current flow.

Increased Cross Section Of Aluminum In Rotary Bars - reduced resistance, better current flow.

Decrease End Turn Length (Windings) - Reduces stray load loses; more efficient.

Like always, it's the engineering details that really do matter...

Another great example of the many VMC parts we sell... Innovators not Imitators

Copyright 2010 VMC Electric, llc All Rights Reserved

Fadal is a trademark of Fadal Machining Centers, we have no affiliation with Fadal or Mag IAS